Die Cutting

Die cutting is the process of cutting shapes from sheets of plastic by pressing a shaped knife edge into one or several layers of sheeting. The dies are often called steel rule dies, and pressure is applied by hydraulic or mechanical presses.

Flat Bed Die Cuts

The main method or standard means of die cutting involves the use of metal dies to give paper or substrate products specific shapes or designs that cannot be accomplished by a straight cut on a web press or a guillotine cutter.

By using knife-edge cutting blades formed into a pattern or die, a machine presses the die into the material to produce the desired shape. Almost any shape can be created and applied to a diverse array of raw materials.

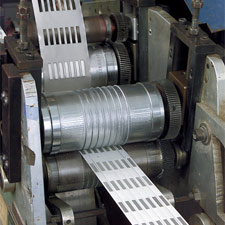

Rotary Die Cuts

Web presses often have a rotary die unit that is utilized for die cutting paper and label stocks. Although there are limitations on the types of dies that can be provided, rotary die cutting serves as an effective method for longer run quantities of printed materials.

Single sheet products require the use of a flat bed die and a flat bed cutting press to die cut the shape into the paper stock. The speed of this process is slower than a web press, but it does provide die cutting capabilities to a wider variety of printed products.

Steel Blade Die Cut Applications

General

Window Envelopes

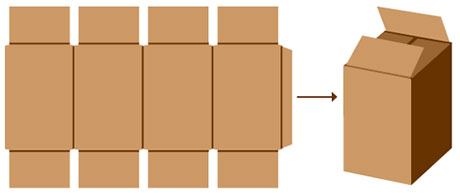

Packaging

Die-cutting areas away from a solid sheet of carton material enables a variety of folding and size configurations to be accomplished.

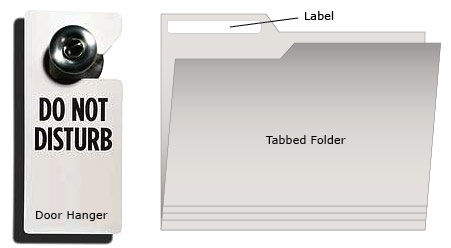

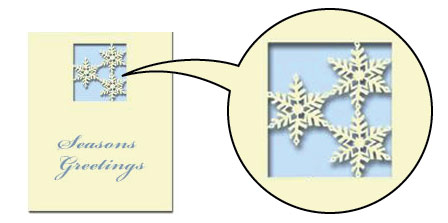

Marketing Materials

A variety of designs can be created to attract attention or provide additional functionality to the document.

Laser Engraving

An alternative method of die cutting, which has been developed in recent years. By using a computer-controlled beam of light to cut through the material, text and images can be accurately reproduced on a variety of substrates.

By using a laser, manufacturers can provide an exceptionally high quality, well-detailed and fine-lined reproduction of intricate art and images or corporate logos.

Unlike a traditional die cut which encounters difficulty in smaller area cuts, a laser engraved die cut can be created to reproduce a 800 dpi (dots per inch) image allowing for a cut impression with a significant amount of clarity and definition.

Note: Always check with the supplier of the product to ensure that the required die cut or perforation can be accomplished on the material desired, with the shape requested, and in the locations indicated