Letterpress

The letterpress process is referred to as a “relief” process because the printed image is produced from a plate in which the image area is slightly raised above the non-image surface of the plate.

Letterpress is one of the oldest printing processes and was the most widely used process until the middle of the 20th century when advances in other printing processes made it obsolete. Flexography, which is an updated version of letterpress, is now the dominant relief printing process.

Printing Process

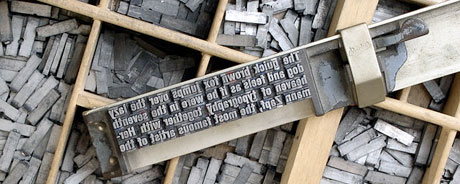

The letterpress process utilizes an ink that is thick in consistency and is well suited for relief printing. A set of rollers deposits the ink on the raised image area of the type or plate, but ink is not deposited on the non-image areas. For this reason, letterpress plates do not require any dampening in order to keep the non-image areas free of ink. This makes the process a simple one and allows for consistent results, but the process still cannot match the quality of more sophisticated print processes.

Applications

Because of the popularity of other printing processes, letterpress is a fast diminishing printing method. It is still used for publishing a few small town newspapers, several types of labels, packaging materials, and some narrow web printing.

An area where letterpress has greater usage than it does with actual printing is with some finishing operations. Old letterpress equipment is used for procedures such as embossing, die-cutting, numbering, perforating, and foil stamping.

The types of products that can be finished using letterpress equipment include embossed business cards and government documents, die-cut labels and folders, numbered tickets and membership cards, perforated mailers, and foil stamped letterheads and invitations.

Press Types

There are three types of relief presses which are described below:

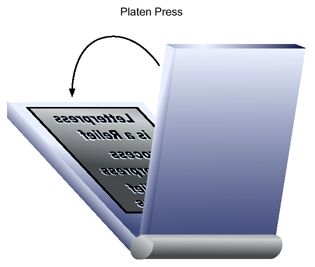

Platen Press

With platen press, movable metal type is locked into a frame called a chase, which is then placed in the press bed and locked into position. A set of rollers applies ink to the type on the press bed and then the press bed and the platen are pressed together which produces the image on the paper.

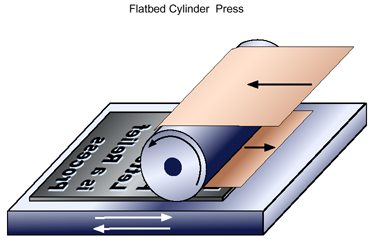

Flatbed Cylinder Press

The type or plate is locked in a chase which is then mounted on the flatbed of the press. Grippers on a rotating impression cylinder pick up a sheet of paper and as the cylinder revolves, the paper is pulled around it. The squeeze between the impression cylinder and the flatbed creates the printed impression on the paper.

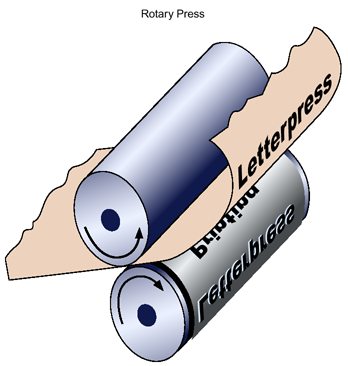

Rotary Press

The plate is mounted on a cylinder where a roller system applies ink to the raised area of the plate. The paper passes between the plate cylinder and an impression cylinder where the resulting squeeze between the two cylinders produces the printed impression on the paper.

A web-fed system also utilizes a plate cylinder and impression cylinder, but instead of individual sheets passing between the two cylinders, the paper is a continuous web unwound from a large roll.

After printing, the web is cut into individual sheets. Web-fed presses are used for larger print runs. Like other printing processes, the letterpress web-fed press usually contains several printing units so that multiple colors can be printed from a single pass.