Thermography

Thermography is the process of spreading thermal powders on the wet ink of a print application and heating it in order to melt the powder into a single solid mass which is raised above the printed surface.

Equipment

Table Top Models

Table top machines were developed in the 1970’s which made it easier for more print manufacturers to offer thermography as an option for their customers. Some table top models involve mostly manual operations to produce the thermographic images.

Floor Models

Larger floor models are fully automated and are attached to and synchronized with press equipment in order to eliminate manual procedures. The printing press may need to be equipped with slow down pulleys in order to be properly synchronized with the thermographic unit.

This can be a very time consuming process and may not be economical to use on runs over a few hundred unless a job is printed with many images per sheet such as a business card application.

The desired speed of the equipment depends upon the design of the application, the materials used, and the type of equipment used for printing the application and for producing the thermographic image.

Applications

Thermography can make the appearance of many print applications more distinctive which cannot be achieved by any other printing process.

Among the many applications that can benefit from thermography are business cards, stationary, invitations, and marketing applications.

Thermographic Process

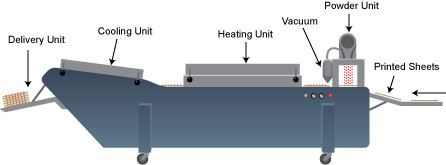

Thermography is successful when the powdered resins are applied to a printed surface on which the printing ink is still wet. This enables the powder to stick to the printed areas. Any powder on non-image areas and any excess powder on the image areas is suctioned off the substrate before the heating takes place.

The heat is produced with electric heating elements that are placed inside an oven or tunnel. The powdered substrate passes into the heat tunnel where the powder melts onto the heated substrate and is fused with the wet ink. When the heating process is complete, the sheet is cooled and the melted powder hardens into the raised thermographic image.

Thermographic Powders

Thermographic powders are made from plastic resins which were introduced in the 1970’s. They have taken the place of resin materials that were traditionally manufactured with a base made from ground tree sap.

There are a wide range of thermographic powders available that produce an endless variety of effects. The powders come in many particle sizes to suit any application. A choice of finishes, such as gloss, semi-gloss, semi-dull, and matte are also available.

In addition to standard powders, the following types of thermographic powders are available:

- Metallic Resin :Â Metallic resin powders produce a metallic sheen after being melted and they are less expensive than foil stamping.

- Glitter : Glitter can be added to thermal resins to produce a sparkling effect after processing.

- Varnish : Varnish can be applied as an all over coat on applications such as four color process jobs to give the images a thermographic appearance.

- Pearlescent Resin : Special ingredients are contained in pearlescent resin along with pigments to produce a pearlescent sheen after the application is processed.

- Static Resistant : The build up of static electricity on the application is reduced with the use of static resistant powders.

- High Viscosity : A high viscosity powder is used to maintain the detail on images that are made up of fine lines.

- Laser Safe Powders : Laser safe resins are treated with ultraviolet light after they are applied and melted on the substrate. This gives the resins the ability to be unaffected by additional heat sources.

All of the above powders can be used alone or they can be combined in various ways to produce multiple effects. For example, adding glitter to metallic resin produces a sparkling effect on the metallic finish. Most resins can be mixed with a variety of substances such as tinsel, sequins, and diamond dust to create even more effects.

Particle Sizes

Different particle sizes are available ranging from fine to course. Fine powder is used on images with fine detail and thin lines. Heavier images can be processed with course powder.

- Fine : A fine particle can be used for most purposes except the finest details and it works well with type sizes from 12 to 30 points.

- Extra Fine : Used for fine details and type sizes 14 point and smaller.

- Medium : Used for solids and types sizes from 24 to 42 point.

- Course : Large solids and type sizes over 36 point are well suited for course powder.

Paper Stock

Some points to consider when selecting a paper stock suitable for thermography are weight, moisture content, color, and texture.

Temperature

Paper stocks must be able to be heated to at least 250 degrees Fahrenheit in order for the process to work properly because the heat on the paper is what melts the resin.

Weight

Paper stocks such as 20 lb. bond cannot handle the high temperature without adverse effects. The amount of thermographic raise that is achieved also changes depending on which paper stock is used.

The heavier and thicker the paper, the more heat is required to raise the temperature of the paper to the melting point of the thermal powder. Some heavily textured stocks may require special resins in order to produce a smooth thermographic finish over the printed areas.

Moisture Content

Paper stocks should have a hard surface and a low moisture content. Excessive moisture in the paper can cause the paper to curl when it is subjected to high temperatures.

Excessive moisture content in the paper can also leave the thermographic image with a cloudy appearance as a result of moisture being released from the paper during the heating process and being trapped in the thermal coating.

Paper that has a moisture content which is too low may absorb the ink so fast that the thermographic powder may not stick to the ink.

Ink

The quality of the ink and the quality of the printed image are directly related to the degree of quality that can be expected when applying thermography to the application.

The ink should be sticky when entering the thermographic device. The tackiness of the ink is what causes the thermographic powder to adhere to the printed surface before it is melted.

If the ink is not sticky enough, the vacuum used to remove excess powder from the non-image area can also remove some of the powder from the image area resulting in substandard thermography.

Inks with little or no drier additives are well suited to thermography because the ink stays wet longer and the ink acts as the adhesive for the thermal powder.

Design Considerations

- Type sizes less than 6 point should be avoided because they can fill in. Type faces that are very fine can also fill in.

- Large solid areas and very small type should be avoided on the same page because each of the elements requires a different type of resin.

- Many print applications using thermography may require special techniques for trimming because the raised print makes it difficult to cut stacks of thermographed sheets using a guillotine cutter.

- The cost of trimming thermographic applications may be more expensive than print projects without thermography. Some applications are sent through special slitting machines in order to be separated.